This is a big innovation from the packaging point of view in presenting this product as it gives aesthetic value and operational benefits and Sustainable. THC gummies are typically packaged in environmentally conscious materials, with some brands opting for paper pulp packaging.

- Eco-friendly Sanctuary: The pulp mold packaging uses sustainable material. Biodegrades and composts best in paper or other natural fiber tea bags. This sustainability point is very much to a section of the consumer base who are eco-aware and for companies that want cut down on their carbon emissions.

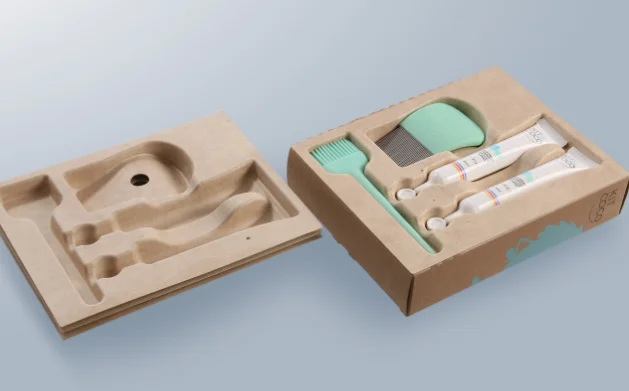

- Perfect Customized Fit and Protection: The ability to provide a perfect customized fit for every product is one of the main features that makes pulp mold packaging so strong. The molds are designed by the manufacturer to fit around items of a specific size and shape. Pulp mold packaging is kind of cushion protection, it can provide good buffer for the products during transmission and circulation to avoid collision damage, shock-proof function helps lower return basics as result.

- Design Flexibility: Pulp mold packaging can be designed to fit a wide variety of product types in many markets. From fragile electronics to beauty products and food items; pulp mold packaging correlates with all kinds of shapes, sizes. Complex designs can be manufactured by the manufacturer that not only offer product protection but are also pleasing to look at.

- Better Customer Experience – The elegant structure of pulp mould helps in delivering a better customer experience. Ultimately, effectively branded products in well-packaged eco-friendly packaging indicate quality and thought. Brands that focus on sustainability and invest in packaging applications to ensure their purchases arrive intact while also being eco-friendly, are appreciated by the consumers.

- Economic production & efficient: Pulmonary emboli packing is economic in manufacturing perspective. Molds and hot presses are used in the production process, with automation between pressings to increase efficiency. Its production scalability is able to cater for high volume productions at a cost effective level.

The pioneering features that pulp mold packaging designs offer include the use of paper pulp packaging as the action counterpart developed for improving product presentation through sustainable fronts. Paper pulp packaging also boasts a recycled, eco-friendly matrix and an ability to customize the fit of your style as readily as its look while offering flexibility and impact protection that translates well from industry to industry for any end use requiring both aesthetics and sustainability.